Instructions

Snath Assembly – Maine Snaths

These instructions describe how to assemble your snath and how to mount the blade for best mowing and ease of use. Read these directions in their entirety before assembling and gluing the handles in position.

Your snath is made in our workshop in Perry, Maine using native white ash for the shaft and birch for the handles. The lower 22” has been treated with a waterproofing solution to protect the wood unless you asked otherwise.

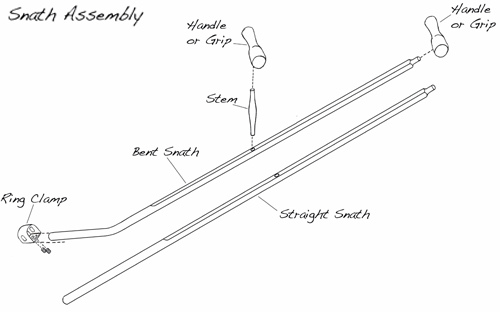

The snath is composed of a main shaft, two handles, stem, ring clamp and a key for tightening the screws in the ring. Handles are marked on their ends with a ‘U’ for the upper handle or an ‘L’ for the lower handle.

Fig. 1

Dry fit (no glue) all parts together lightly for position before gluing in place. Position the handles at comfortable angles. It helps to practice-mow to find a comfortable position for the handles. Record these positions with a pencil line where the stem meets handle and snath and on the upper handle and tenon. When gluing the pieces together you can line up the pencil marks to reproduce the original positions.

Each end of the stem is tapered and wedges into tapered holes in the lower handle and shaft. The tapered stem and holes form a tight fit when driven together with a few moderate hammer blows. There should be no play once these pieces are assembled. If the lower handle does not fit well on the stem try the other end of the stem or sand the stem to fit. (Moderate blows – refers to the judicious use of force. Use enough force to firmly drive the parts together, but not enough to split or damage the parts. Use your best judgment.)

The tightness of the upper handle and tenon varies with humidity. High humidity swells the wood creating a tight fit. This makes it difficult to seat the upper handle on to the tenon. In this the case, setting the parts in a warm, dry environment will draw the moisture out. Sanding the tenon to reduce the diameter will solve the problem more quickly.

Lower humidity causes the upper handle to be loose on the tenon. Leave the parts in a moist environment to swell before assembling. Do not soak in water. Another option is to wrap a thin piece of cloth soaked in glue around the tenon then put the handle on while the glue is wet. Apply glue to tenon and hole, as well. First dry fit the handle (no glue) with only the cloth to ensure a good fit; too tight a fit and the handle may split.

To protect the wooden parts during assembly use a wooden mallet or butt end of a hammer handle to tap the handles into place.

We recommend yellow woodworkers glue like Franklin Titebond or a similar product. Gorilla Glue or epoxy work, too. Spread a light coat of glue on both joining surfaces. Join the pieces with a slight twisting motion back and forth to spread the glue. Some glue should squeeze out of the joint. Line up the pencil marks and use moderate blows to set the pieces home. Use a damp cloth to wipe away the excess glue. Follow the glue manufacturer’s instructions and allow the glue to set for the time required. The joints may be pinned for reinforcement by driving a small nail part way through them. Be sure to drill an undersized pilot hole through the pieces first to prevent splitting. With a proper glue job pins are not necessary.

Fig. 2 shows how the assembled scythe is held when mowing. The long end of each handle points toward the mower at approximately 90° to the shaft. The handles may be rotated slightly if you find a different position more comfortable. It is important to dry fit the parts (no glue) then use the scythe to find the most comfortable position for the handles. Take the time to find a comfortable handle position. It’s worth it.

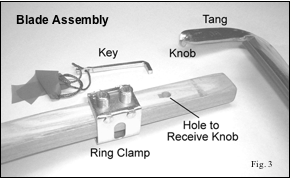

Blade Assembly

(Fig. 3) To mount the blade loosen both screws on the ring clamp. Slide the clamp over the end of the snath, set the blade so the knob of the tang fits into the hole drilled in the snath. You may have to tap the knob to seat it into the hole. You may also have to tap the ring over the tang the first time the blade is mounted.

Slide the clamp up about midway over the tang and finger tighten the two screws. Snug them up with the key. Do not over tighten the screws. Moderate pressure evenly applied will hold the blade securely – take up a little on each screw alternately. Check the screws frequently when the blade is first used. The blade will seat into the wood as you work so the screws need adjustment during this break-in period. If you mow in very wet conditions you may need to loosen the screws to compensate for swelling of the wood.

Slide the clamp up about midway over the tang and finger tighten the two screws. Snug them up with the key. Do not over tighten the screws. Moderate pressure evenly applied will hold the blade securely – take up a little on each screw alternately. Check the screws frequently when the blade is first used. The blade will seat into the wood as you work so the screws need adjustment during this break-in period. If you mow in very wet conditions you may need to loosen the screws to compensate for swelling of the wood.

Setting the Hafting Angle

The hafting angle, or the angle of the mounted blade in relation to the snath, is extremely important to get right. A closed hafting angle will make your mowing easier than an open hafting angle. You can see the different hafting angles in Figs. 4 & 5. The Scythe Book, pages 17 and 176, describes two methods of setting the hafting angle and another method is shown on our Workshop webpage.

Fig. 5

Fig. 4

Here's an easy way to set a closed hafting angle. Mount the blade on the snath and set the ring midway up the tang. Tighten the screws finger tight allowing the tang to pivot side to side within the ring. With a right hand blade let the blade fall to the right so the tang rests against the ring. With a left hand blade let the blade fall to the left. Tighten the screws to hold the blade in place. This creates a closed hafting angle which is best for most mowing conditions. With a closed hafting angle the mowing is much easier than with an open hafting angle. You may find that a slightly open angle works better. Don’t be afraid to experiment with different hafting angles but avoid a fully open angle as shown in Fig 5.

The tang may slip inside the ring while mowing so check the hafting angle each time you stop to stone the blade. If it has shifted reset it. If you feel the blade shift inside the ring while mowing, stop, check the position of the tang and reposition it as needed. Carry your key with you when you mow. It fits comfortably in a pants pocket or looped under your belt.

Note: An open hafting angle occurs when the tang slips backwards to rest on the back of the ring. It is a common cause of difficult mowing and prevents the blade from cutting on a slice. Instead, the blade hacks at the grass trying to mow too much at a time. Hard, tiring work results with the likelihood of a broken snath or blade. An open hafting angle is an easy problem to solve if you take the time to check each time you hone the blade.

If the blade continues to slip regardless of screw tightness sand the mating surfaces (tang and snath). Placing a thin piece of leather, or a doubled over strip of sandpaper with the abrasive facing outward between tang and snath may help. The best insurance against slippage is to mow with a smooth, fluid stroke so the blade slices instead of hacking at the grass. If you have to jerk the blade along you are not slicing. Slicing allows you to mow with little effort.

Hafting Angle for TOPS Blades:

Because of the tapered tang the quick & easy way of setting the hafting angle can result in too much angle. Try one of the methods shown in The Scythe Book on pages 17 and 176 or on our website (Workshop). Set the toe about 1-1/2” below the beard.

Care & Storage

Unless we have been specifically asked not to, the lower 22” of the snath has been coated with a waterproofing sealant. No other sealer is needed. The metal parts will benefit from an occasional oil coating. Beware — WD-40 will dissolve and smear the black coatings on some of our blades. Store the scythe clean and dry. Don’t stand the scythe up with the blade at floor level, you risk stepping on it or bumping into the point or edge. For temporary storage lay the blade over a sawhorse or object of similar height. For longer storage hook the blade on a nail overhead against a wall. Loosen the clamp screws slightly. Alternatively, remove the blade and store snath and blade separately. An old burlap or cloth seed bag, a denim pant leg or cardboard & duct tape can be fashioned into a quick, protective sheath. Make sure the cover can breathe so moisture evaporates. Canvas blade covers are available from Scythe Supply.

Hammer Sharpening

The traditional method of preparing the cutting edge is called peening. Peening takes advantage of the plastic nature of steel. A hammer and small anvil or a jig is used to evenly strike the cutting edge of the blade (a zone about 1/8" inch wide) drawing out & thinning the edge, establishing the correct edge shape for intended use. Peening also hardens the metal enhancing edge retention. After peening use a whetstone to hone the edge and to maintain the edge during mowing. The whetstone gradually wears away the peened edge increasing its angle so you have to re-peen to restore correct angle and thinness. Frequency of peening depends on many factors. It may vary from a few hours to several days. When the edge loses its keenness after a few mowing strokes it is time to peen. Remove the blade from the snath before peening.

Fig. 6

Mounting the anvil or jig: Mount the anvil or jig at a convenient working height. Do not mount in a bench vise. A better situation is to mount them in the end of a log. For details of making a peening log see the attached handout “Making a Peening Log”. Ready made peening logs are available from Scythe Supply.

Peening lies somewhere between the force of jewelry making and blacksmithing. The hammer redistributes the metal slightly with each blow. Think of the steel as very dense modeling clay. It can be coaxed into shape by moderate, repetitive force. Heavy hammer blows are not necessary. A solid yet sensitive strike that makes a good rebound is your goal.

Hammer & anvil — The blade is held so the cutting edge is in contact with the crown of the anvil. The hammer blows are aimed at the cutting edge (a zone about 1/8” wide). The blade is gradually moved between strikes of the hammer. Coordinate the movement of blade with the frequency of hammer blows to peen evenly. Keep the blade edge flat on the anvil crown. When peening on an anvil most of a blade’s final sharpness is the result of good hammering. The whetstone only finishes an already sharp edge.

Fig. 7

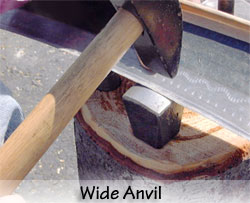

Anvils come in two varieties, wide (Fig. 7) and narrow (Fig. 8), each producing the same effect. The wide anvil is used with a 16 oz. cross peen hammer. The blade is held with its bottom (convex) side to the anvil, the hammer striking the edge of the blade from the label side.

The narrow anvil (Fig. 8) is used with any 16 oz. flat faced hammer. The blade is turned over so the edge on the label side contacts the anvil while the flat of the hammer strikes the edge from the back (convex) side of the blade.

Fig. 8

A new blade may take several passes to produce a good edge. Don't try to do it all in one pass of the blade's length. Set an easy sustainable rhythm and work the blade from the beard to the tip. Examine the results after each pass and start over again if necessary. With good light you should be able to see the results of the hammer blows. The metal will expand forward and become thinner. The force of your hammer should be more like a jeweler than a blacksmith. As your edge approaches final thinness lighten the force of the hammer. The finished edge will be about the thickness of heavy paper.

When do you stop? That depends on what you plan to mow. A wide, thin cutting edge that is good for fine, tender grass will break if used for dried grass or tough, woody stems. For heavier work keep the hammered area narrow to support the cutting edge and make it stronger. Experience will guide you to the best compromise of a sharp, effective edge that will hold up to occasional rough use.

If the blade has a wavy appearance it is over-peened and about to crack or tear. Stop peening. Use the blade with care checking it frequently for damage while mowing. Avoid too thin areas at subsequent peenings. These places will wear back to thicker metal as you mow and stone the edge.

Fig. 9

Peening Jig — Fig 9. The same sensitivity and guidelines that apply to the hammer and anvil also apply to the jig. The jig is a cylindrical anvil with a center guide post. It comes with two caps or dies that shape the edge and fit over the post. The cap marked with one ring is used first to establish a primary bevel leaving the edge slightly ‘U’ shaped. The cap with two rings finishes the edge giving the final shape; beveled on top, flat on the bottom. The second cap is used more frequently when peening an already sharpened blade.

To use, place a cap over the jig's post, slip the blade under the cap in very light contact with the post. Keep the blade flat on the jig face. Gradually draw the blade under the cap as you tap the cap with a 16 oz, flat-faced hammer. With each tap of the hammer move the blade sideways about a 1/16” or 16-20 taps per inch of blade working from beard to toe. Allow the cap to rotate for even wear of the contact surface. Again, light taps of the hammer are more effective than heavy blows in shaping the edge.

You may have to make multiple passes to bring the blade to useable condition if it has gone a long time without peening. Keep your supporting hand close to the jig for better control. When your grip on the blade has moved out of the comfort zone, stop and relocate your position. Support the overhang of the blade on your knee or thigh. Choke up on the hammer handle to find a comfortable balance point.

The beard of the blade is fairly flat but the cross-sectional curve of the blade increases towards the toe making it difficult to keep the edge flat on the anvil face. Listen to the sound of the hammer as it strikes the cap. The sound should be a solid ‘THUNK’; steel on steel all the way down. If the strikes sound tinny or hollow adjust the position of the blade slightly to re-establish that solid sound. Sometimes a slight flex or relaxation of your thigh muscles or wrist is enough to bring the blade back into the proper position.

The toe of the blade comes to a sharp, thick point. This is called a ‘stone point’ and is meant to take a blow and protect the blade or at least limit damage. Most blades can only be peened up to a ½” or so from the stone point.

Peening with the jig shapes the edge. It does not sharpen it. As the cap does its work the steel is drawn out against the center post leaving a dull edge. When peening is complete your must use your whetstone to sharpen the edge. Use the narrow faces of the stone not the broad and sometimes rough faces. Hold the blade in a comfortable position. Place the stone so it rests on both the cutting edge and the back rib of the blade. This establishes the proper edge bevel for the blade. Diagonally stroke the stone down across the edge and slightly towards the toe sharpening 4-5” of the edge. Pick up the stone and move it closer to the toe repeating the stroke and overlapping the previous stroke a bit. Work your way down the blade from beard to the toe. Do this until you can feel the edge is keen or there is a burr on the underside of the edge. Turn the blade over, bottom side up, and stroke the stone lightly over the back of the edge towards the rib to remove the burr. The blade should now be sharp for mowing.

The Scythe Book has several chapters in the addendum devoted to proper edge profile, peening with a jig, honing and blade repairs. Please, take the time top study them. They provide many good tips on edge maintenance. Our DVD Peening and Sharpening European Scythes is helpful in learning to use the hammer and anvils, peening jig and sharpening. You can find details about other equipment on our website at www.scythesupply.com/equipment.html

See our full list of articles.

back to home